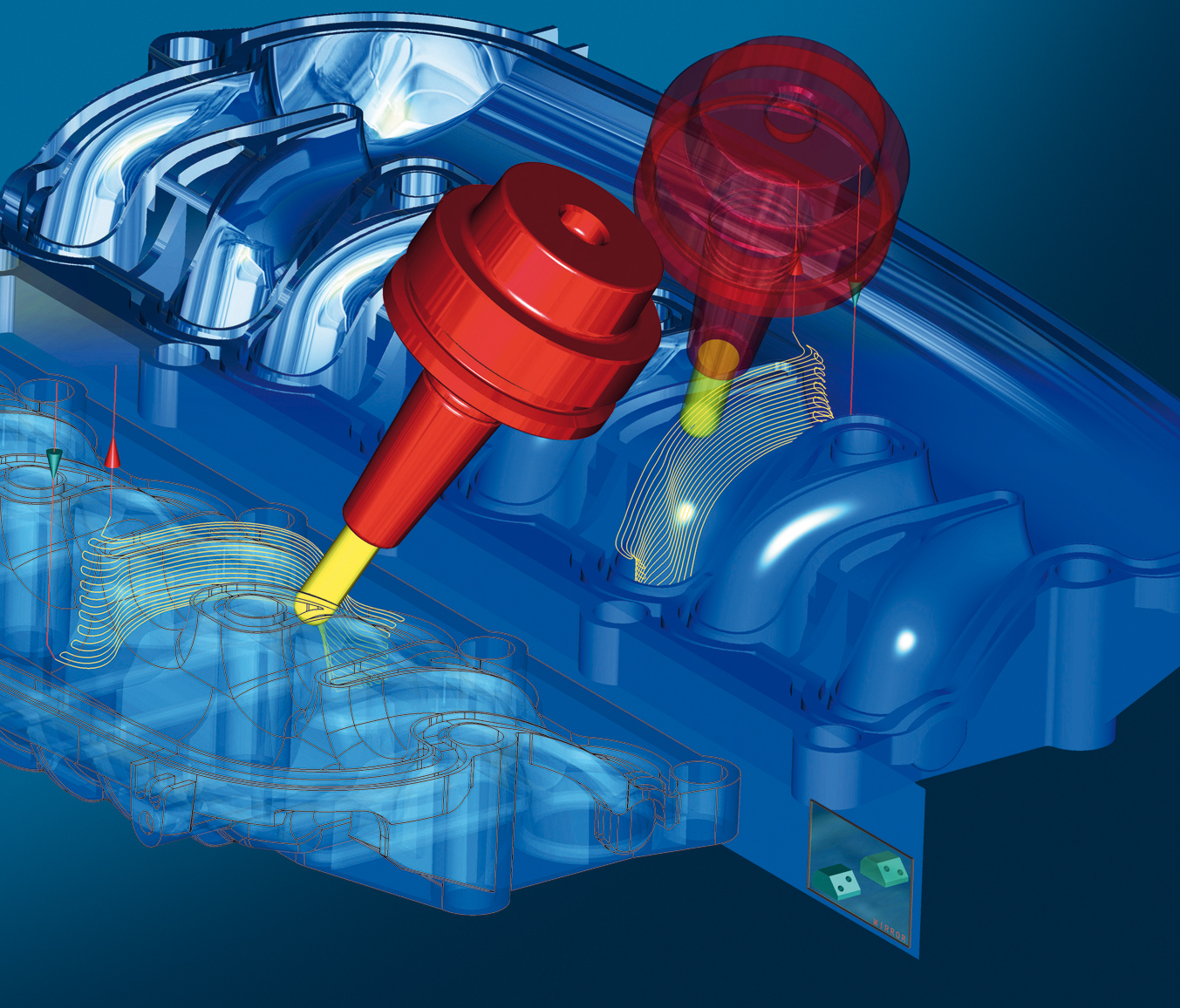

Machining complex geometries with deep cavities, high steep walls and undercuts requires multiple changes in the installation tool in limited areas of milling. It includes standard and special machining strategies, as well as a large number of optimization functions that enable you to set processing operation based on the task and user requirements.

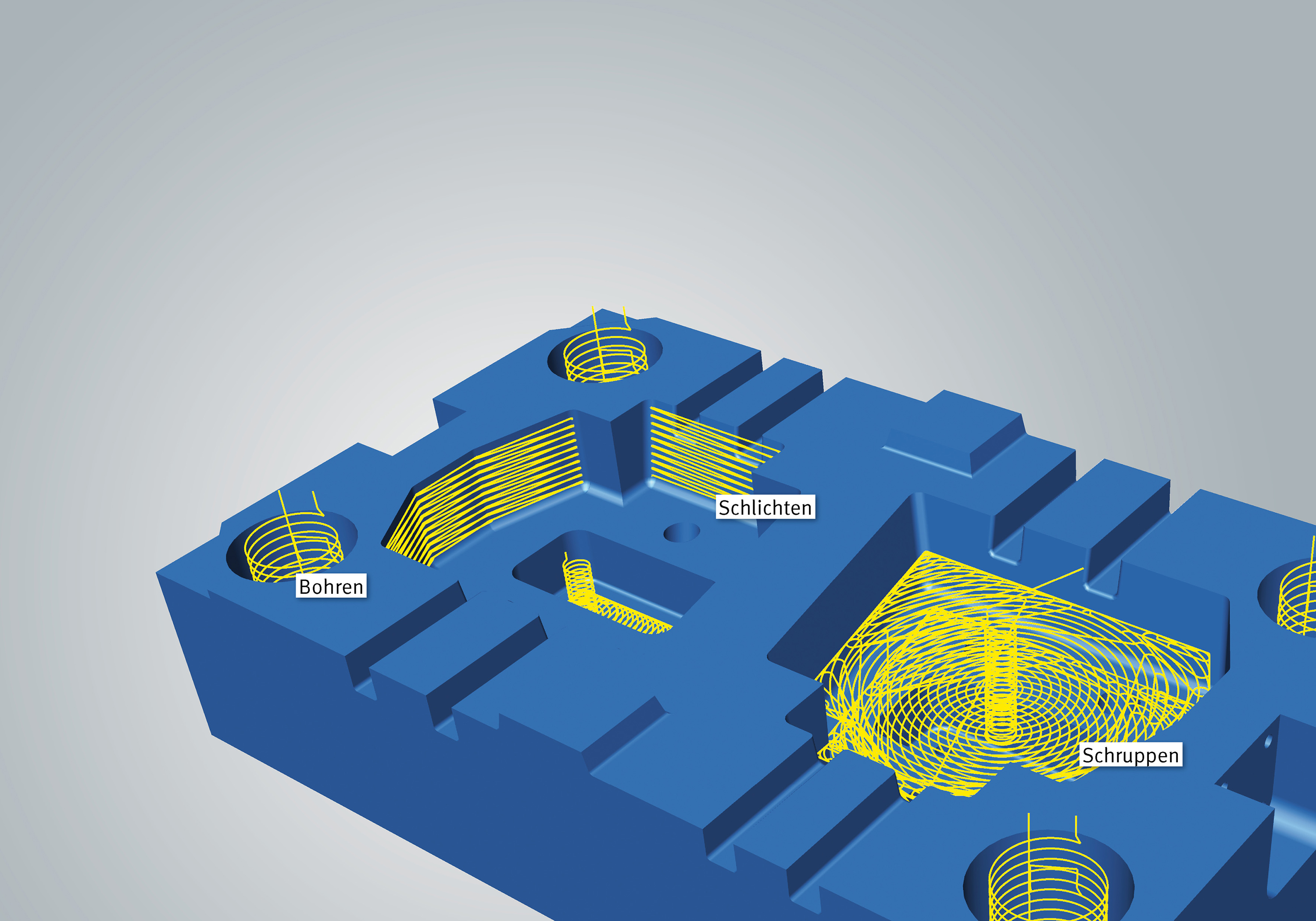

This component is used for complex tasks 2D- and 3D-processing and for high-speed processing and processing of hard metals. The app includes optimization features that allow you to perform the processing based on user requirements. This component is suitable for 2D- common tasks-and 3D-processing and provides the user with ample opportunity for effective programming. Its unique feature is that, in some cases, milling pockets and holes produced with the support of management cycles and intelligent features of machine tools. This component is suitable for 2D common tasks. These include technology fitcherov and macros, automatic functions, such as a function of reflection and transformation, job binding function and mode of production that reduce the time spent on ancillary operations, as well as the automatic validation and exception collisions. In addition, hyperMILL provides many other opportunities for automation software, allowing to reduce processing time and optimize processes. With a variety of strategies for handling possible complete machining of parts without changing tools. HyperMILL allows you to program both simple and complex geometry. Machining with hyperMILL 2013.2 SP1 x86圆4

Hypermill openmind full crack#

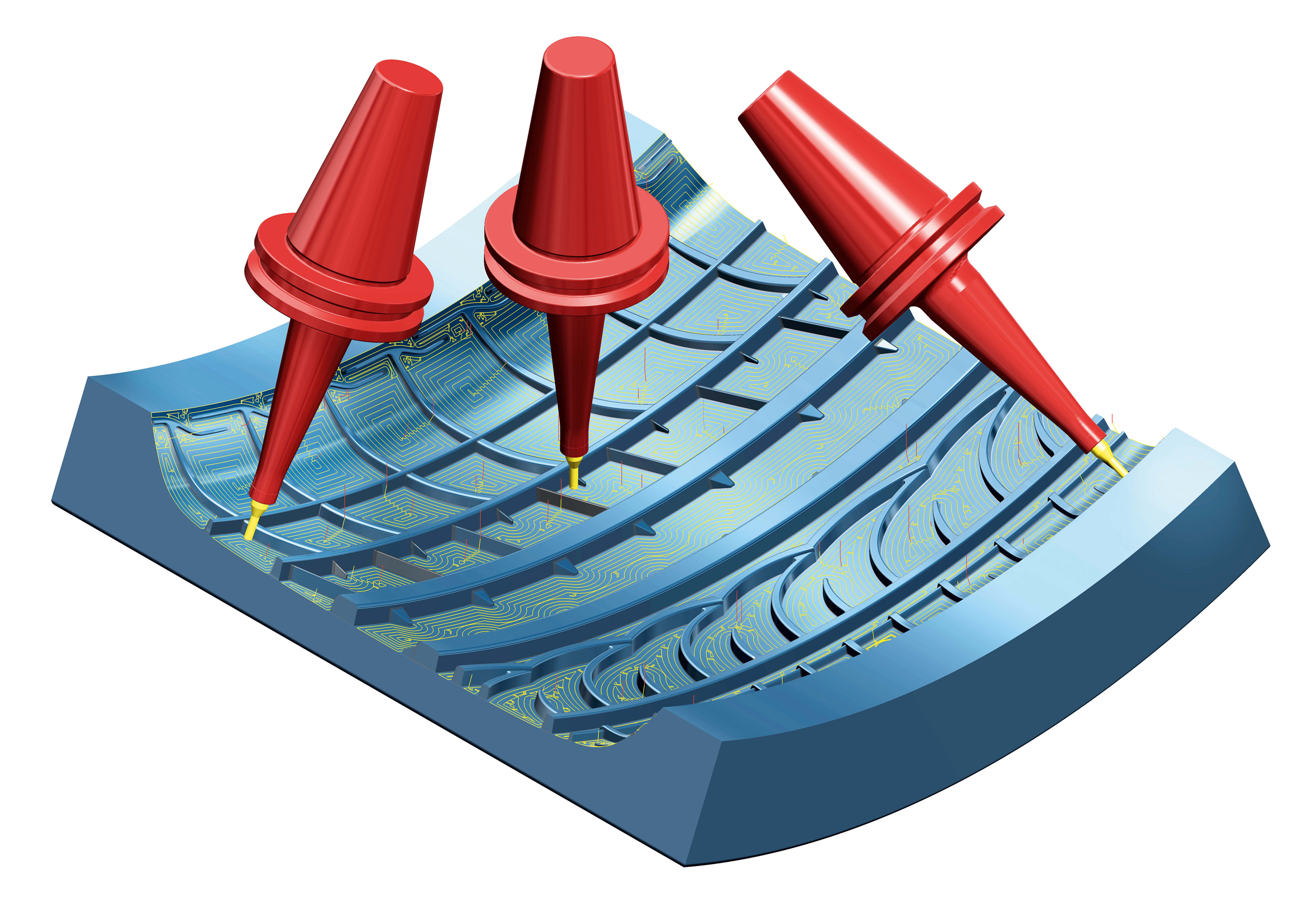

The tool travels close to the workpiece while being checked for collisions and it is not retracted to a clearance plane between movements, drastically reducing cycle times.Download hyperMILL 2013.2 SP1 x86+圆4 | hyperMILL 2013.2 SP1 full crack The various operations, whether 2.5D, 3D or 5-axis, are linked in such a way that auxiliary processing times are shortened. If a 3-axis movement is not possible due to detected collisions or axis limitations, the hyperMILL VIRTUAL Machining Optimizer changes the movement with the aid of a fourth or fifth axis. This allows greater speeds to be achieved during the movements.

The rotation axes are moved along the shortest path, and the movements of the linear axes are minimised.

Hypermill openmind software#

The software from OPEN MIND optimizes infeed movements and automatically determines whether positioning is faster with the aid of a rotational axis. Fork head machines can also be used with the Optimizer to enable dynamic machining. This method enables spiral machining in a limited machine. The tool then gently approaches again and machining continues. If there is an axis limitation, the Optimizer interrupts the tool path, gently retracts and rewinds the axis to avoid the limitation. For example, if a machine has a limited axis rotation, the software takes this into account when selecting tool positions and ensures smooth machining. The Optimizer can also detect other possible problems. This gives companies greater flexibility when it comes to assigning machining capacity. CAM programs can be created completely independently of machine properties because the simulation software automatically adjusts to the machine in use and it performs comprehensive collision checks. The Optimizer ensures efficient and safe machining operations.Īnother major advantage of the Optimizer comes into play when programming on a wide variety of machining centres. The hyperMILL VIRTUAL Machining Optimizer analyses complete machining sequences with powerful optimisation algorithms while considering axis limitations. Given the high degree of complexity, it is difficult to determine the effects on all subsequent machining steps and make decisions about the best overall solution. This allows programmers to avoid errors when manually optimising axis positions. The hyperMILL VIRTUAL Machining Optimizer automatically finds the best solution for collision-free orientation with efficient traverse movements for multi-axis machining. This enables the users to overcome the complexity associated with alternative setup and orientation options in 5-axis machining. The machining process is simulated by using a digital twin.

0 kommentar(er)

0 kommentar(er)